Objective: D65 is a type of horn of Diameter 65mm and mainly consists of a resonator and a diaphragm which are separated by an air column which is responsible for the functioning of the horn. The resonator of the horn is 0.6mm in thickness and attached to the diaphragm with the help of a washer. The resonator consists of three humps in its design. The functioning will be best when the frequency of the air gap and resonator match or are almost equal and this is analyzed by various FEM methods.

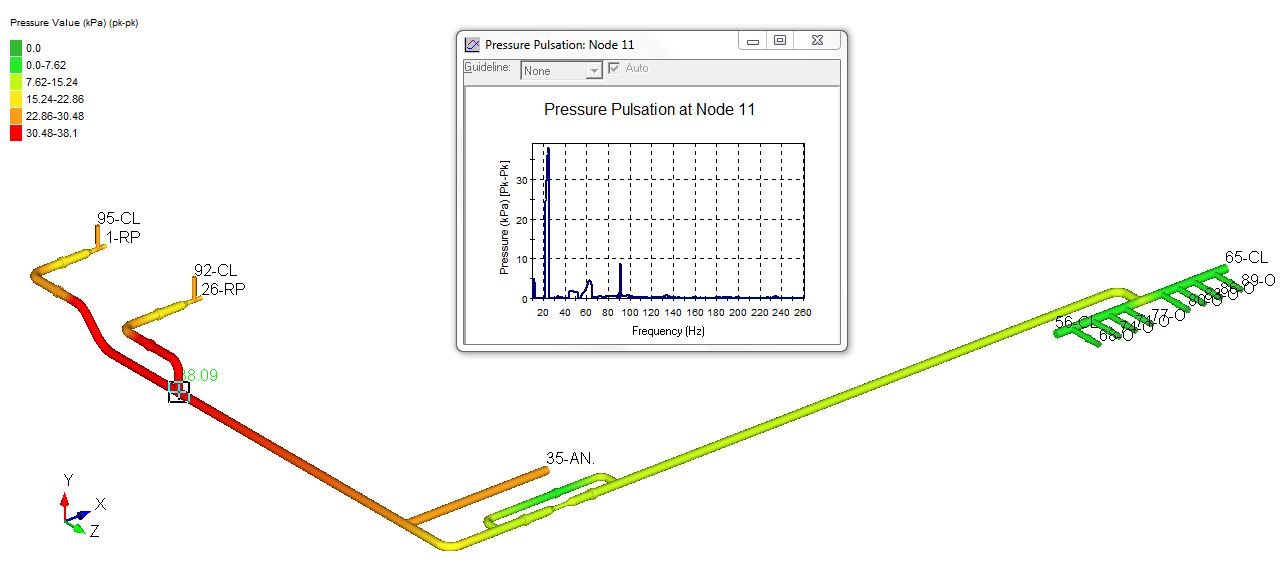

Methodology and Analysis: By using FEM we can easily find out the frequency of the resonator but the frequency of the air column is a fluid-solid interaction(FSI) problem. Advanced FEM algorithm was used for the air column frequency and then by iterative method the frequency of both were matched . From the analysis done, some factors which can improve the design are modifying the dimension of the washer between resonator and diaphragm, like 0.5, 0.8, 1.0 etc and modification in the thickness of the resonator. Analysis is done by using different thickness of the resonator for different dimension of the washer. Few of the results are shown in the image.

Result and Conclusion: From various analysis done it can be concluded that the dB and quality of sound depends on the natural frequency of the air column and natural frequency of the resonator. Smaller the gap the better will be the quality of sound in the particular range. Since 0.6mm is the actual thickness of the resonator which upon analysis was modified to 0.4mm so that the air column volume was increased and hence the quality of sound improved. After changing the thickness and the profile the output is found to be good i.e. 0.4mm thickness and base is up from second hump and outer side by 0.8mm. Hence the resonator design was optimized to produce maximum sound with high quality.